Recently, lithography technology and etching machine have been the hot topics in today's discussion. It can be said that lithography technology is the soul of chip manufacturing, and etching machine is the soul of chip manufacturing. If you want to produce processing chips, these two items must be.

The simple expression of these two devices is that the lithography technology projects the schematic diagram onto the monocrystalline silicon chip covered with lithography technology, and then the etching machine etches the unnecessary schematic diagram on the monocrystalline silicon chip which has just drawn the schematic diagram. It seems that there is nothing difficult, but there is a brand image that describes that the power circuit structure on each processing chip has become thousands of times larger It seems to be more complicated than all Beijing, which is the difficulty coefficient of lithography technology and etching.

The whole process of lithography is to coat the surface of the silicon wafer with a layer of lithography technology (a kind of colloidal chemical substance that can be etched by light), and then irradiate the surface layer of silicon wafer (similar projection) through a mask according to the light source (processing difficulty coefficient UV < deep UV < extreme ultraviolet). Due to the covering of lithography technology, part of the irradiated part is eroded Some of the sunlight is left behind. These are the necessary power circuit configurations.

There are two kinds of etching, one is dry etching and the other is wet etching (popular at this stage). To put it bluntly, wet etching is to add ice in the whole process. After reflecting the round crystal of lithography technology with special chemical solution, the remaining part is the power circuit structure. At present, the dry etching has not completed the commercial service mass production, and the basic principle of etching machine is the root According to plasma technology, the chemical solution is replaced, and part of the silicon circle is removed.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

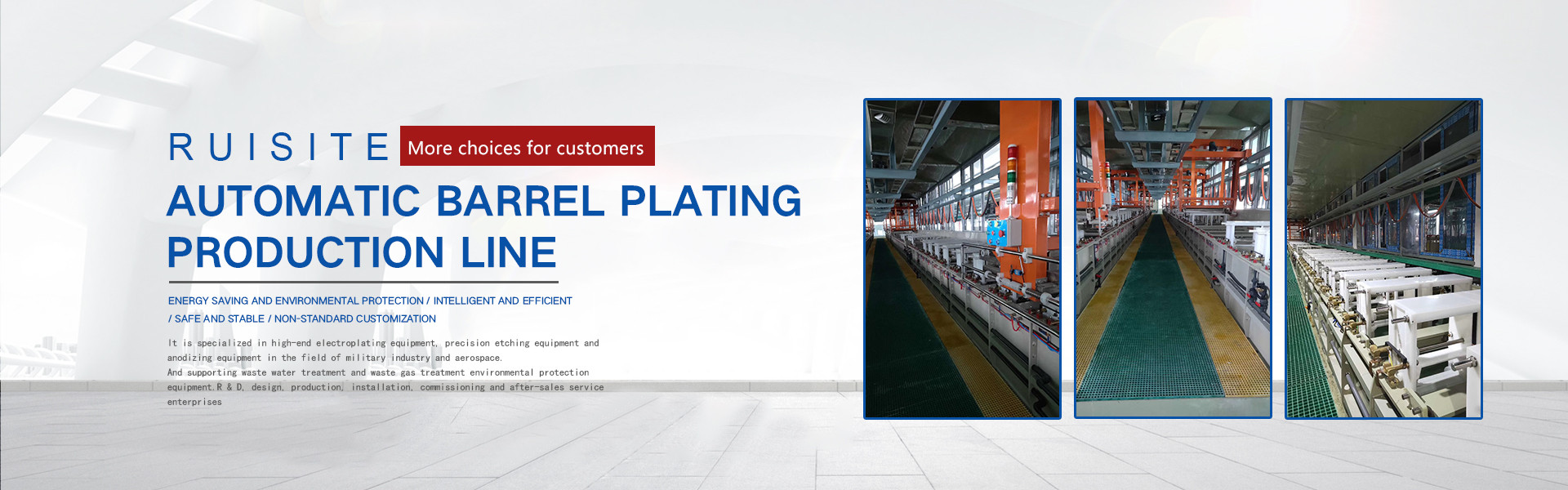

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

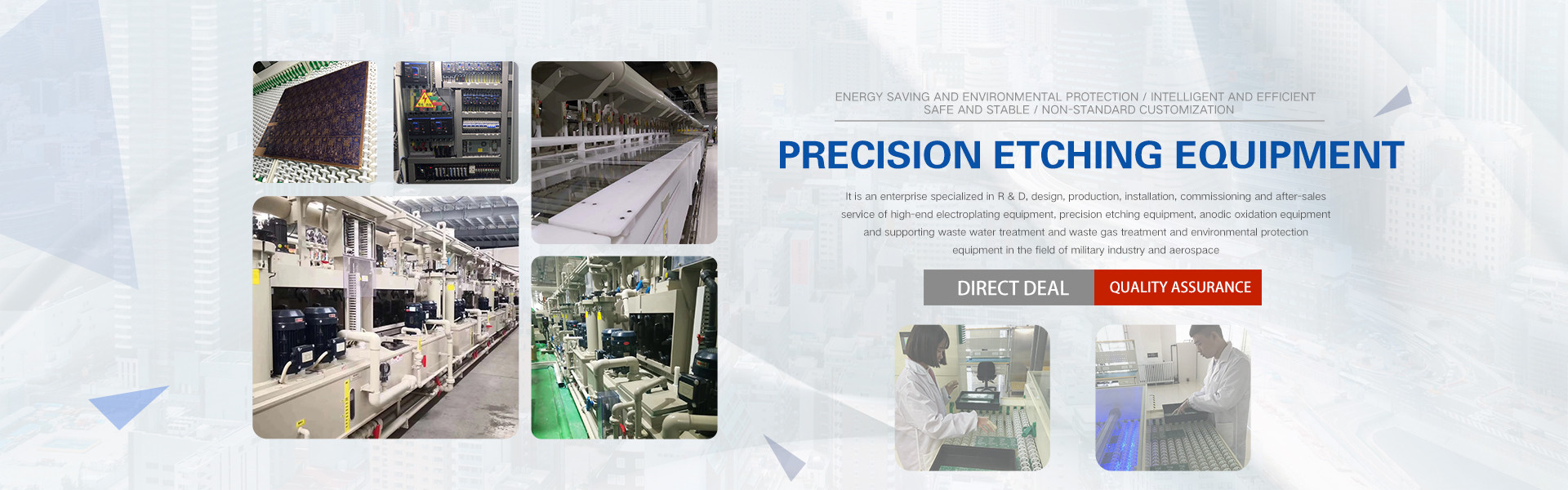

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(简体)

中文(简体)

Hot keywords