Due to its environmental protection, simple manufacturing and processing technology, low maintenance cost and other advantages, laser has become the preferred choice of most manufacturers. Laser etching machine is used for routine maintenance of high-precision optical instruments, which can not only reasonably reduce the equipment failure rate, improve the production and processing efficiency of machinery and equipment, but also reduce the cost of products.

In daily maintenance and maintenance, try to ensure the cleaning of machinery and equipment, and ensure that the office environment is clean. The electronic optical components of laser etching machine equipment are mainly composed of crystal and spectacle lens, and the surface layer is coated with fine film. Dust will not only weaken the power of the laser, but also continue to destroy the film on the surface of electronic and optical components when it is more serious, so that the electronic and optical components are damaged or damaged, resulting in the failure of machine equipment Often at work.

In the usual maintenance, if there is dust on the surface of electronic optical components, the dust can be gently blown away by blowing bubbles against the surface layer of electronic and optical components. It is forbidden to blow air at the surface layer of components immediately by mouth. If you can't remove the stains on the surface of components with blowing bubbles, you can gently scrub the surface of components with cleaning cloth, and you can also use cotton and alcohol (purity above 95%, analytical purity) to gently scrub the surface of components.

At this time, it should be noted that the hand can not directly touch the coating surface of the components (special tools such as medical tweezers, finger protection or rubber gloves can be used), and the scrubbing should be along one direction.

Suggestions for maintenance of key components (frequency can be adjusted according to the application of machinery and equipment)

1. In case of abnormal conditions, disconnect all switching power supply and carry out inspection again;

In a certain area, the temperature of the laser generator should exceed the normal temperature;

3. Keep the room and machine surface clean and tidy;

4. Regularly maintain whether the electronic and optical components of the etching machine have environmental pollution, and clean them up if there is environmental pollution;

5. There is no need to press the hydraulic lifting platform to avoid the reduction of precision.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

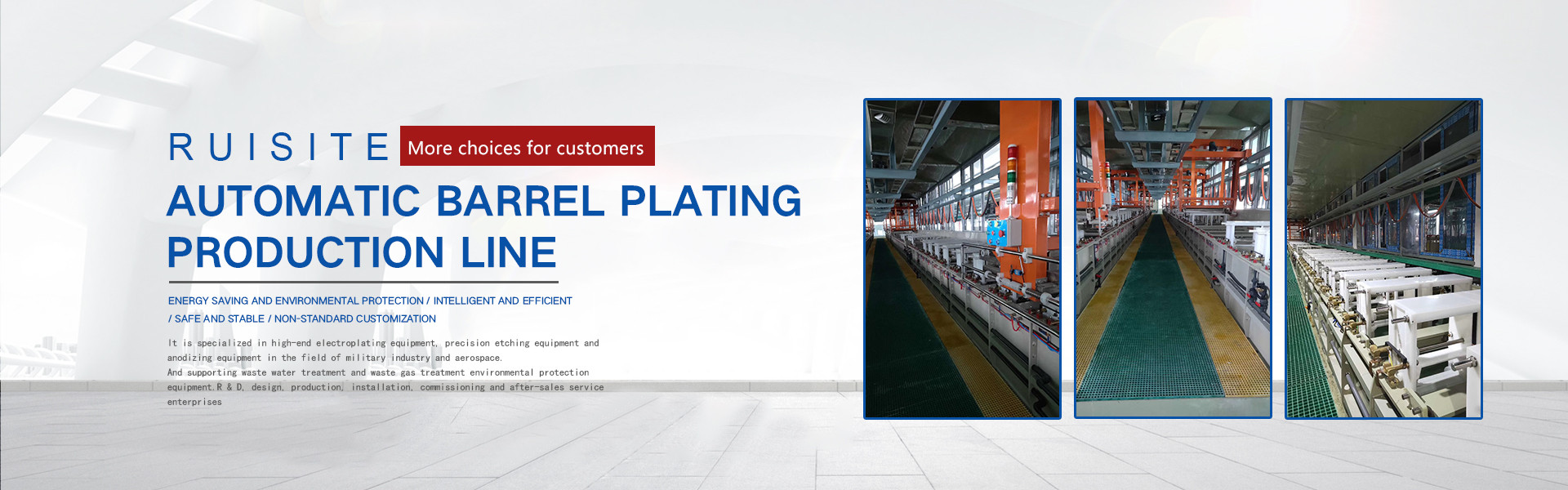

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

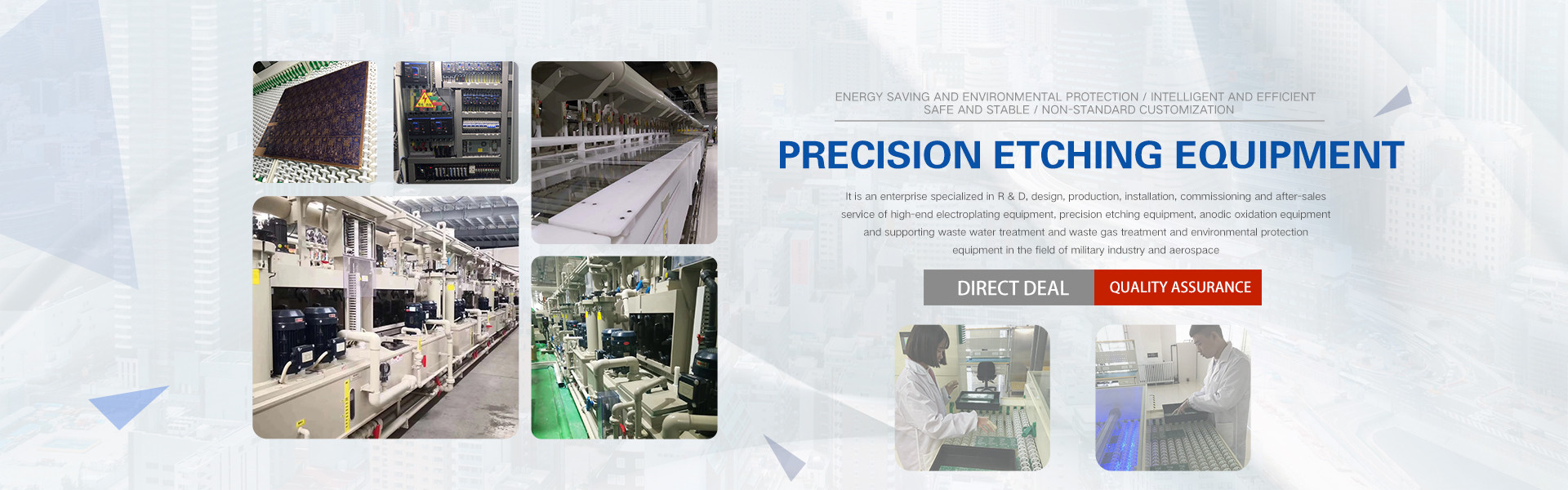

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(简体)

中文(简体)

Hot keywords