The key technologies of electrochemical corrosion pretreatment are: light induction etching, ink printing, sticking self-adhesive label. Each processing technology has its own advantages and disadvantages. Etching machine manufacturers can select the corresponding processing technology according to the specific provisions of their own products. The following is a practical interpretation of the differences between the three processing technologies:

1. Photoresist etching: Frankly speaking, the solution to the exposure of developer is the choice of photoresist etching. The production process is: sizing / spraying → baking → exposure → developer → etching → stripping → finished products; the applicable precision of photoresist etching process is higher, such as stainless steel mesh etching piece, stainless steel screen, lighting lighting decoration, case etching, hardware crafts The traditional ink printing and self-adhesive label are difficult to achieve such requirements, and the light sensitivity should be solved before etching. Screen printing film can be self-designed, low-cost, and can be reused for many times;

2. Ink printing: ink printing is widely used in the fields of stainless steel engineering board, elevator car board and advertising signs. It is suitable for a kind of pattern design to make a batch of goods. The production process is as follows: screen printing ink → drying / drying → etching → whitening → stripping film → washing board and air drying → covering sub film → finished products. The etching process of ink printing is relatively simple, and the design of etching pattern is relatively simple, The precision is not high, and the cost is also small;

3. Self adhesive label: it is widely used to label the advertising industry. The larger feature of self-adhesive label is convenient coloring (spraying) in the middle and later period. The design of self-adhesive label can be output on the computer by itself. The production process: sticking the self-adhesive label → etching → cleaning → air drying → spray coloring → baking at high temperature → tearing off the self-adhesive label → finished products.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

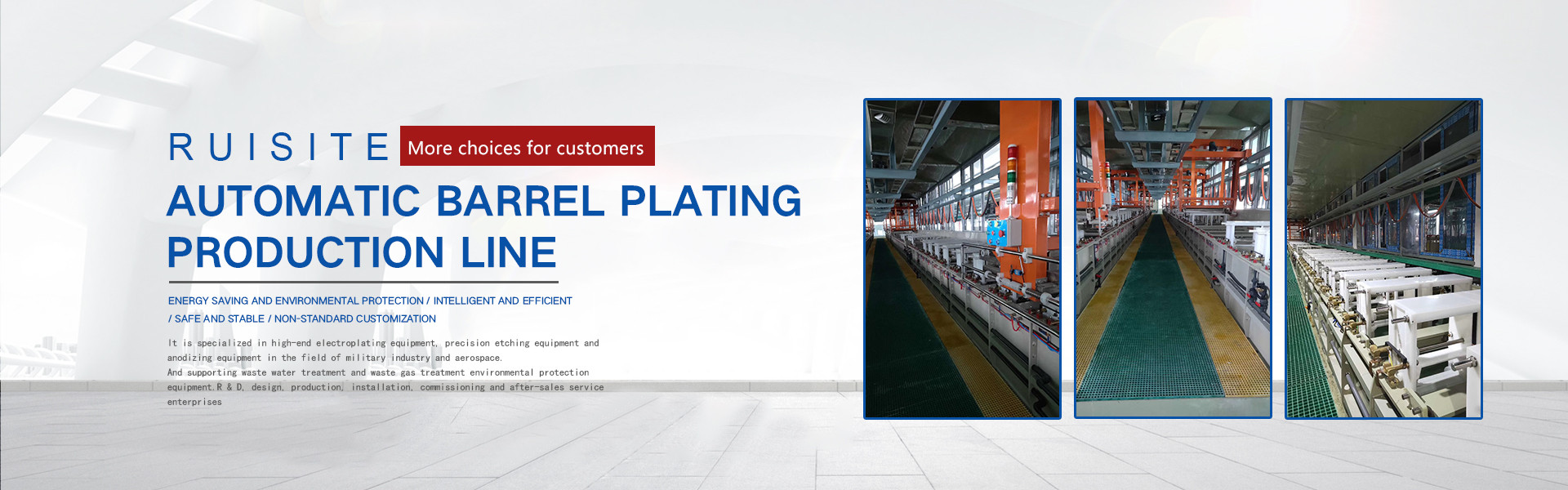

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

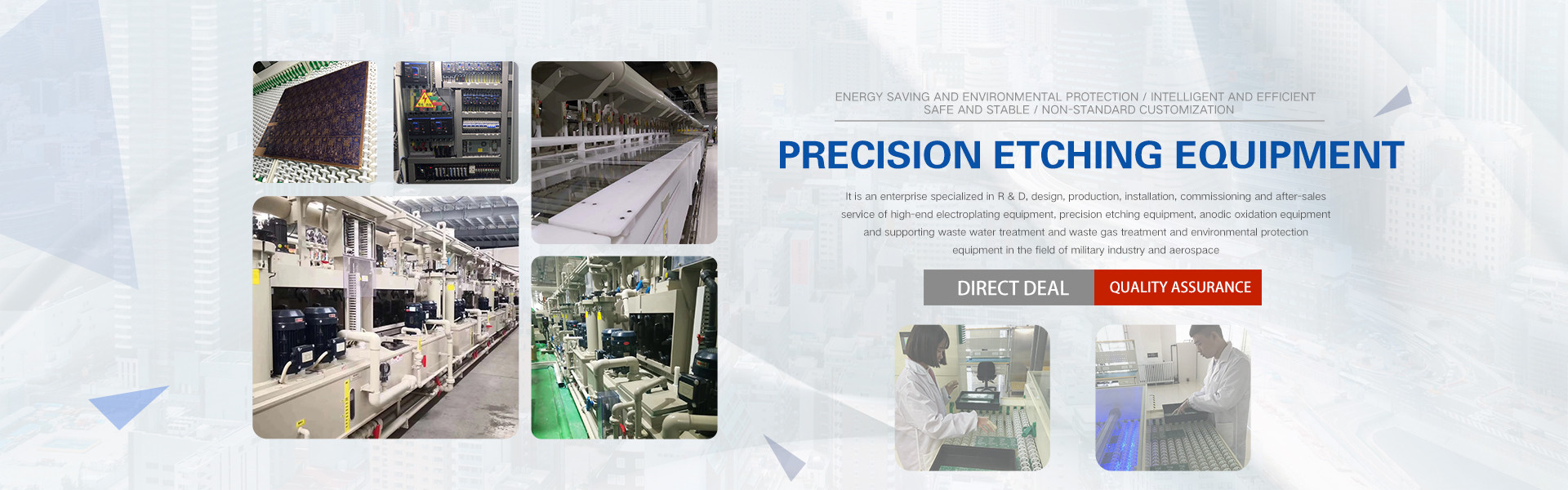

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(简体)

中文(简体)

Hot keywords