The traditional plating process of electroplating equipment generally includes non-ferrous plate bottom plating, upper layer plating, laser plating, secondary plating, stripping varnish and spraying protective film; while plastic plating refers to the process of coating metal materials on plastic surface by electroless nickel plating and electroplating.

Plastic electroplating is the technology of the integration of new materials, new technologies and new processes in today's processing technology. It broadens the application scope of traditional definition electroplating, and creates a brand-new and upgraded industry for the development trend of electroplating equipment field. It can be called a "magnificent return" of traditional definition electroplating process, and has broad industry prospects.

After electroplating metal material layer, plastic products keep the characteristics of light weight, high quality and low price, high production and processing efficiency, and have the characteristics of metal material appearance, conductivity, heat transfer and aging resistance. Nowadays, plastic electroplating has been widely used in electronic devices, optical equipment, CNC lathe keys and light industrial products.

Plastic electroplating technology still has more complex production process and processing technology limitations, such as poor credibility of plating solution, difficult practical operation, unstable coating quality, very easy to appear black spots and other defects. But now we have developed and designed a new type of immediate catalytic reaction or electroplating plastic, which can shorten the production process and improve the credibility of the coating.

In the aspect of improving the compressive strength of plastic parts, the chemical fiber of raw materials is shortened or the particles are doped with small particles to produce high toughness polymer materials. In addition, the pre passivation process of plastic electroplated parts can achieve satisfactory practical results.

It should be considered that plastic is a conductive medium and can not be electroplated immediately. It is necessary to use the method of accumulating conductive ceramic film to transform it into conductive negative electrode.

Therefore, the plastic electroplating equipment has put forward higher requirements for the type of plastic, product modeling design, production and processing technology. Today, the general types of electroplating plastics are ABS, polypropylene and polyester, among which ABS plastics are widely used, and the actual effect of electroplating is.

Considering that unsuitable product modeling design will cause part of in-situ stress of commercial products and reduce the coating interfacial tension, it is required to prevent a lot of plane drawings of Electroplated Plastics, and all edges and corners need to be rounded. In addition, it is not suitable to be too thin, and the thickness does not need to change suddenly to ensure the coating quality.

Because the surface defects of the plastic parts will become more and more obvious after electroplating, the surface smoothness of the mold shell is required to be very high. The actual effect of decoration design such as metal drawing, optical rotation, cosmetic repair and sandblasting process still needs to be done on the mold shell, In order to make it more convenient to take out the mold, the mold shell should be manufactured to a certain slope according to the orientation of the mold.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

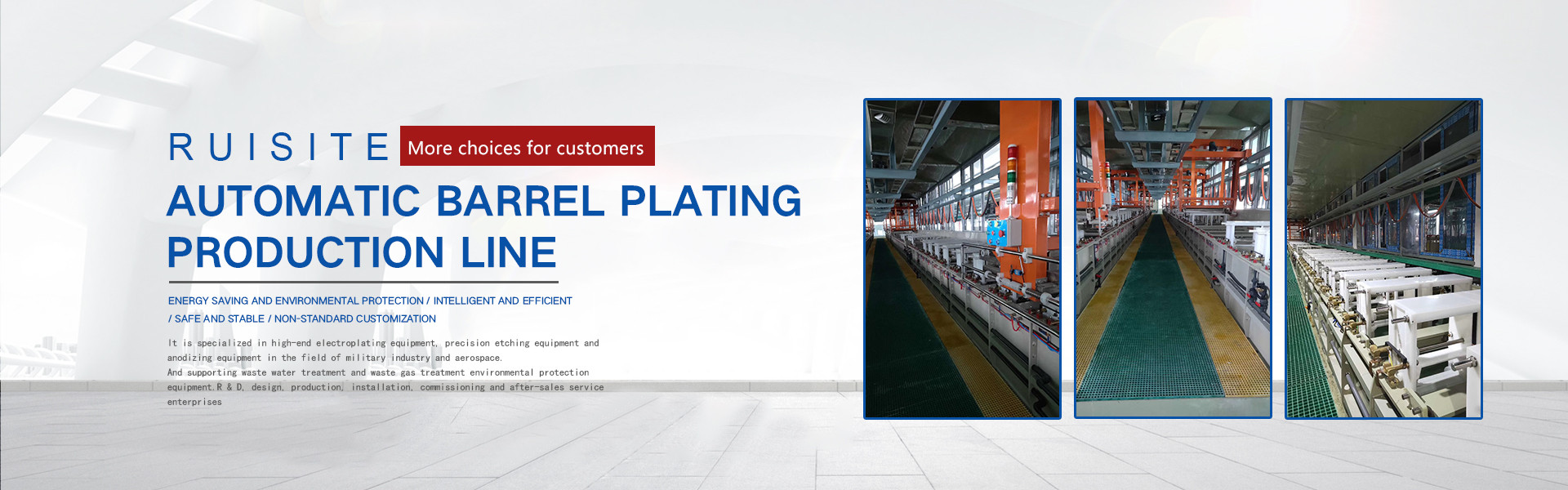

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

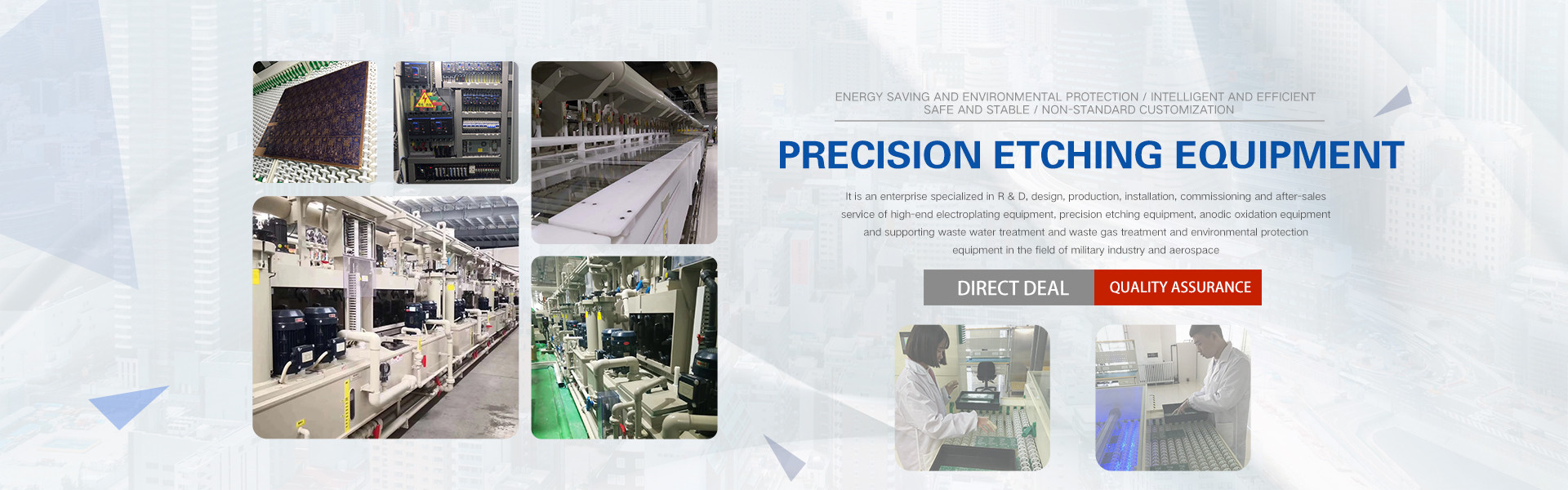

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(简体)

中文(简体)

Hot keywords