Electroplating equipment manufacturers in the processing process must be auxiliary equipment and efficiency. With the rapid development trend in China, electroplating equipment manufacturers have become an indispensable part of the production line. In order to be able to better in accordance with the professional laws and regulations in industrial production, not only the ring transformer and electroplating tank, but also some auxiliary industrial equipment and mechanical equipment must be provided to ensure that all electroplating processes and surface treatment processes are carried out normally. It contains essential instructions for moving or mixing machinery at negative level, heating or freezing equipment, electroplated liquid respiratory tract or fume filter and its electroplating process manufacturing process tank (such as electric shock device, electrode wire, anodic oxidation treatment solution and anodic oxidation treatment solution basket, electroplating n). It can be seen that auxiliary mechanical equipment plays a leading role in industrial production.

1. Negative stage moving or mixing machinery

In industrial production and manufacturing, the whole process of some seed vaccination is carried out in the electric control box or under the mixing and shaking specifications, so as to improve the current flow in the work. It is an important role of electroplating process solution, can avoid rabbit sharp injection and edge hair

Hair. In the whole process of electroplating process, the expected effect of firing and so on.

2. Water cooled radiator or electric heating device

As the bath as far as possible in the essential temperature work, so try to install electric heating device in the bath. For example, bright nickel coating requires the bath temperature to be kept at 6O ℃ C, the temperature of stainless steel plate should be kept at 50-65 ℃, and the acid should be bright barrel roller layer or bright

The nickel / silver coating should be less than 40 ° C as far as possible.

3. Attention and respiratory care

In order to better ensure the quality of the whole process of electroplating process, the electroplating process solution should be fully considered every quarter. Some electroplating must also take full account of the residual respiratory tract. Filtration device is a common mechanical equipment in petrochemical industry, electroplating equipment has China's standard mechanical equipment.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

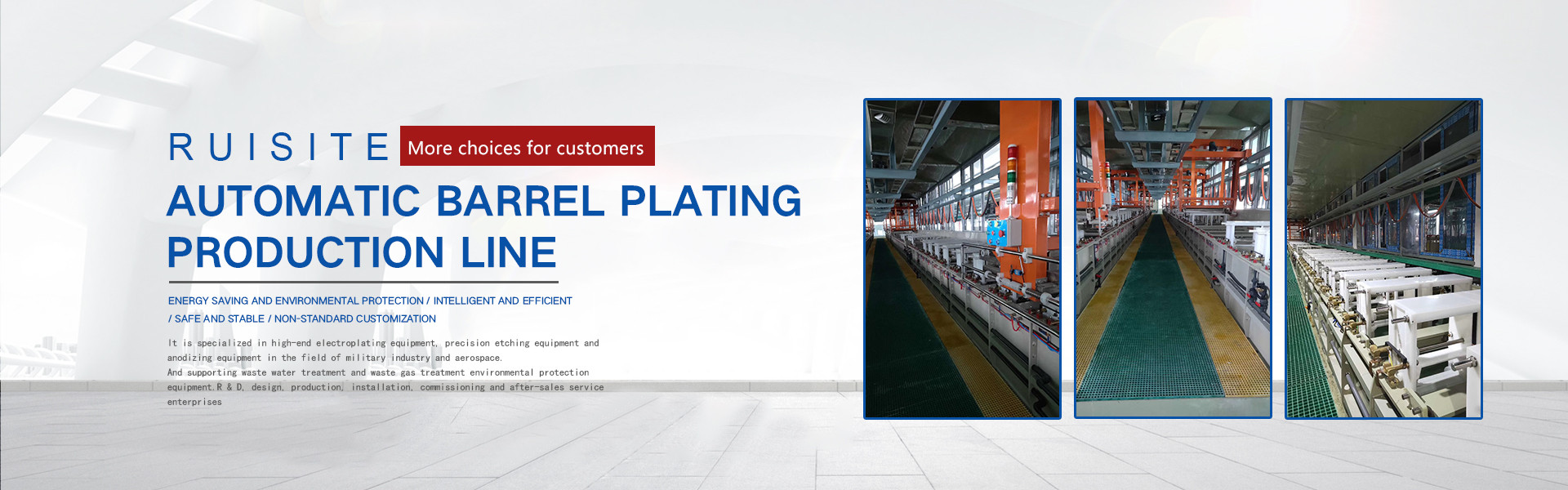

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

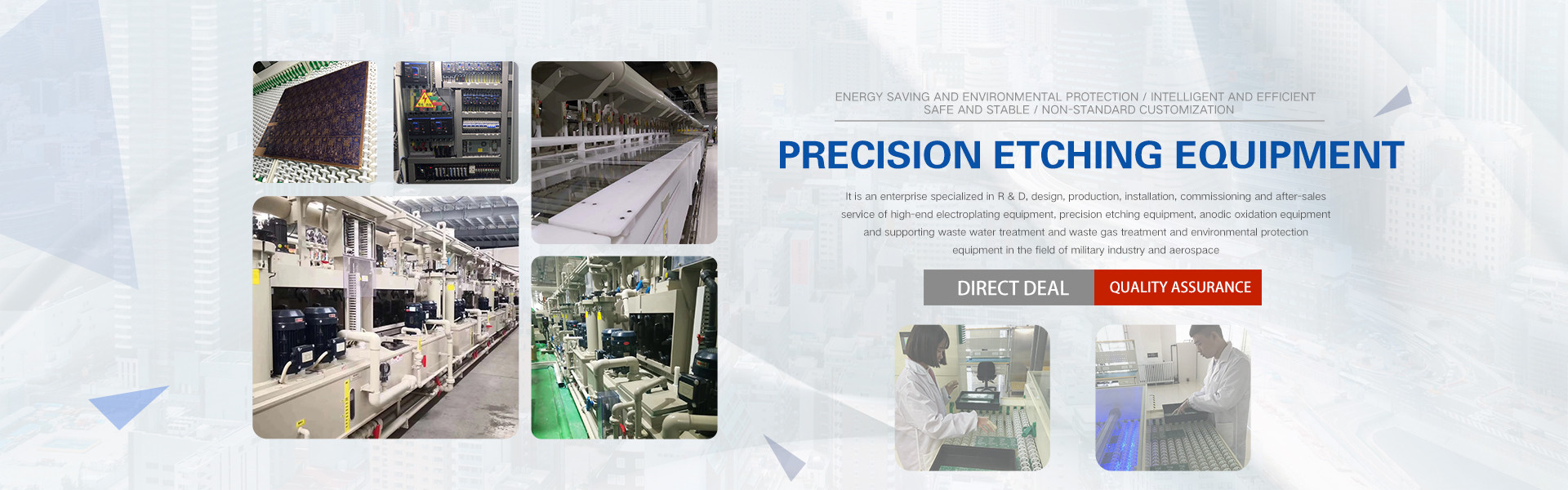

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(简体)

中文(简体)

Hot keywords